Welding Cells | Welding | MCK Welding | São Paulo | Brazil

MPR1 2000

The MPR1 2000 cell was developed for welding parts that require rotation during the welding process. It features a workstation with a guillotine door and can work with parts up to 2000 mm in diameter. This compact and efficient cell provides perfect, standardized welding of parts and/or products across a variety of market segments.

Resources

Suitable for parts with a maximum dimension of 2000x800 mm that do not require rotation;

Optimized robot workspace;

Reduced dimensions to occupy a smaller factory area;

Quick device exchange system;

Single base for easy installation and movement;

Cell-integrated security systems;

Uses high-quality components that provide low maintenance;

Uses robot and power supply from the same manufacturer for perfect communication and synchronization;

Cell composition

Estun Robot: ER8-1450

Welding Source Estun: EC 350

Estun Torch: ERG500

Robot pedestal

A workstation with 01 automatic or manual door

Monoblock base

Protective enclosure in steel sheet

Maintenance door

Visual signaling

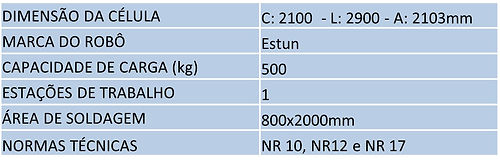

Technical Specifications

MCK Welding 's robotic cell solutions can be developed according to the Customer's specifications and needs, using any brand of industrial robot and welding source.

Services Included:

Issuance of the NR-12 safety risk report and ART;

Cell installation and operational training at the customer's plant2;

40 hours of robot programming2.

Notes:

1. Transportation of the cell to the customer's plant not included.

2. Travel expenses (travel, food and accommodation) not included .